Company > Sustainble

NATURPIEDRA - SUSTAINABLE DEVELOPMENT - ENVIRONMENTAL PRODUCT DECLARATION (EPD)

Sustainable development

The development model chosen by Naturpiedra can be described as sustainable because it is economically viable, socially just and environmentally sustainable, and our company strives to maintain a reasonable balance between these three types of development:

In economic terms, the activity carried out by Naturpiedra directly or indirectly benefits the population of the surrounding area. It should be noted that it currently provides economic support, with approximately 100 direct jobs (extraction, production and installation of natural stone), plus numerous indirect jobs inherent to its activity (transport, maintenance, etc.). This ensures a sustainable economy for the present and future of Bernardos and its region, maintaining its productive activity.

On the social side, the creation of an industrial fabric in an unpopulated rural area is of great importance, with direct and indirect jobs in an activity deeply linked to the environment. The extraction and manufacture of Naturpiedra Jbernardos materials is carried out in Bernardos (Segovia), ensuring a fair social development for the present and future. It is a historical activity, rooted in the past of the area (the first slate quarries opened in Spain, five centuries ago), which provides great cultural wealth for the benefit of the locality and the environment.

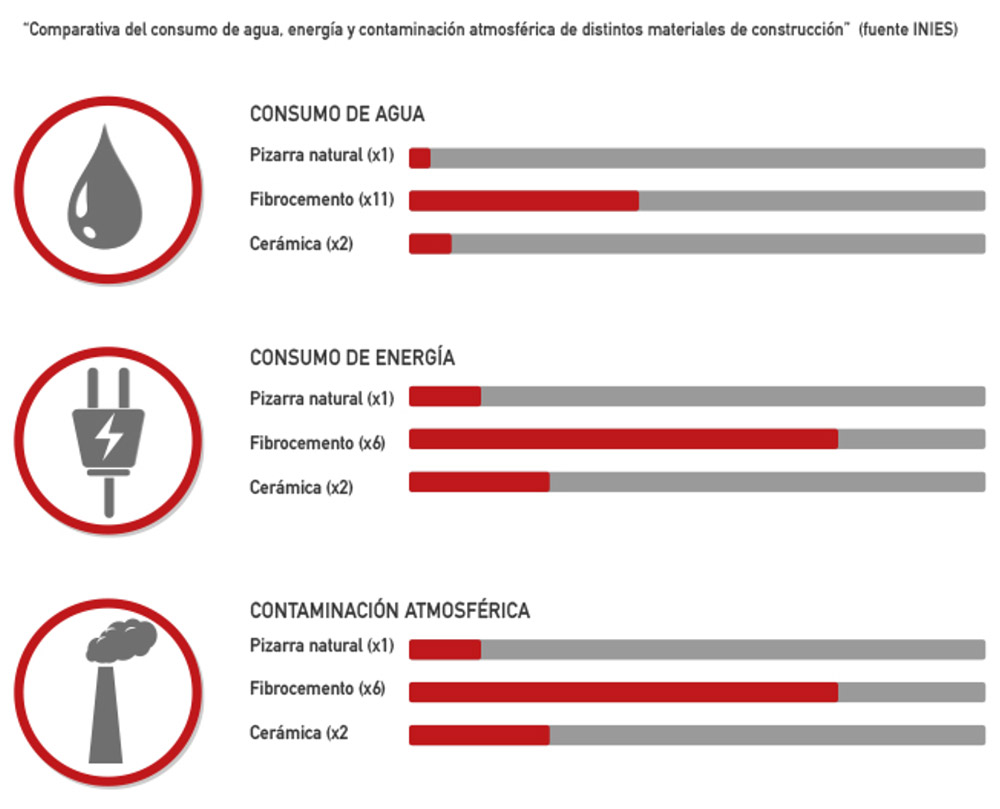

The environmental aspect is the most important aspect of sustainable development, taking special care of environmental sensitivity during the extraction and manufacturing processes. From the treatment of inert waste (natural stone does not generate any contamination) in controlled dumps, recycling products used in the industrial process, such as the essential water (generating a minimal water footprint), or the sludge from the cutting process. Very important at this point is the lower energy incorporated into the production of stone compared to products of equivalent uses, such as ceramics, for example. Generating a really low Carbon Footprint (amount of greenhouse gases). We are also committed to self-consumption of energy and therefore we have installed solar panels that generate. 540 Wp, with an energy production capacity of more than 360,000 KWh, approximately 40% of the total consumption of the factory which has its headquarters in Bernardos. At the Villanueva del Pardillo headquarters, the installation provides more than 60% of the electricity consumption of the facilities and the surplus energy generated is fed into the grid.

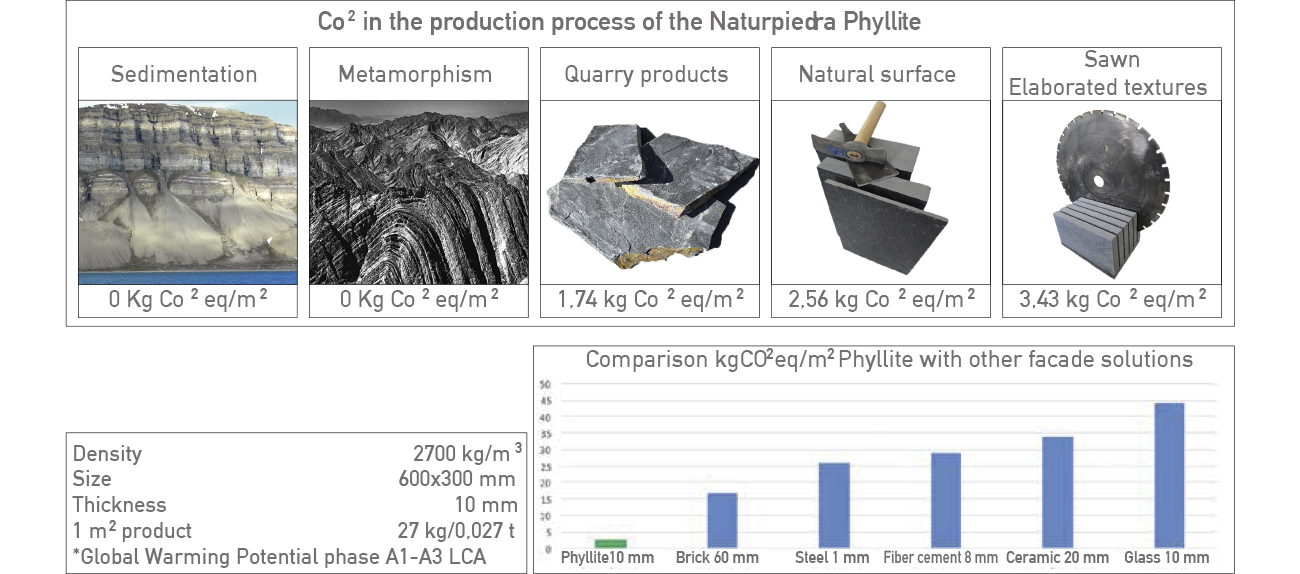

Phyllite, Naturally Sustainable

Naturpiedra phyllite is a natural stone that has been used in construction for five centuries. A sustainable product with multiple uses: ventilated façades, roofs, paving and exterior and interior cladding, among other applications. Being a 100% mineral and natural material formed over thousands of years, it is authentic and inimitable, has a great durability in its constructive use and is fully recyclable.

Advantages of Natural Stone in Construction:

1. Decreased heat gain in buildings.

2. Significant savings in electricity consumption in air conditioning.

3. Significant improvement in the thermal comfort of the building, without air conditioning.

4. Reduction of peak electricity demand.

5. Use of more economical air-conditioning installations with lower consumption.

6. Prolongs the useful life of the roof system, reducing maintenance costs.

7. Mitigates the “heat island” effect between 1 and 2ºC, by transmitting less heat to the outside.

8. Reduction of pollution and CO2 emissions.

9. The high SRI index contributes points to environmental certifications.

Its density and composition also offer us an acoustic insulation and fireproof material (class A1), to which it is not necessary to add artificial and potentially toxic components. Other benefits that natural stone brings to buildings is its almost zero maintenance and its great durability, even beyond the buildings where it is applied, and can even be reused in new constructions.

All this results in both energy and economic efficiency, being a very cheap material if we take into account its long useful life and the accumulated energy savings.

Energy efficiency

After the manufacturing phase and considering its use in construction, perhaps the most important value contributed by natural stone to efficient and sustainable construction is its high energy efficiency, far above other artificial materials, such as porcelain stoneware or prefabricated concrete.

As a thermal insulator, it contributes to greater energy savings and comfort, thanks to its good thermal inertia, which results in lower CO2 emissions. Its low solar reflectivity and thermal emissivity also helps to mitigate the “heat island” effect.

Environmental Product Declaration

The environmental profile is an increasingly important criterion in the choice of building materials by consumers, both public and private.

On its way to consolidate itself as an ecological and sustainable company, Naturpiedra has achieved the Environmental Product Declaration (EPD) for the Filita from its quarries in Bernardos (Segovia); in all the formats and finishes marketed:

- Natural texture.

- Disc cut and elaborated textures.

- Quarry products (masonry, slabs and slabs).

An Environmental Product Declaration (EPD) is a standardised document or report that provides quantified and verifiable information on the environmental performance of a material. It assesses the environmental impact throughout the life cycle of the product, in accordance with the international ISO 14025 standards, where the requirements to be fulfilled are gathered and verified by an authorised external official body; and the European Standard EN 15804, which facilitates the recognition of the environmental information of construction products in Europe, a consensual and recognised reference.

EPD is of great importance in compliance with the European Construction Products Regulation, or in the environmental certification of buildings such as LEED, BREEAM or GREEN.

To achieve the EPD, both Naturpiedra and two other external and independent actors such as the technological centre NOTIO and the state standardisation company AENOR intervene.

NATURPIEDRA, once its product has been identified, informing about its characteristics, uses, composition and performance (corroborated by technical tests). I analyse the real data obtained in the manufacturing process throughout the 2020 financial year. Detailing the work and energy consumption, from extraction in the quarry to the output of the processed material, packaged and ready for consumption. Data that is improving day by day thanks to the optimisation of the factory with new machinery, reduction of hydrocarbon or explosive consumption, reuse and purification of water in a closed water cycle; and above all, the recent installation of photovoltaic panels for self-consumption of electricity.

NOTIO analysed and certified the Life Cycle Analysis (LCA) of the Naturpiedra Filita, following the specifications of the UNE-EN ISO 14044, UNE-EN 15804 and UNE-EN ISO 14025 standards, which define the requirements and guidelines that this type of study must comply with. They measure the Carbon Footprint or environmental impact of the material throughout its cycle of use:

Product stage analysed by Naturpiedra.

Construction and installation stage on site.

Use stage, where factors such as minimum maintenance, long useful life (estimated at 75 or more years) or the great capacity of natural stone as a thermal and acoustic insulator, which provides great energy efficiency, are analysed.

End of life, in which it is shown as an inert material, harmless to the environment, as well as reusable and recyclable.

Data that provide numerous benefits in the overall calculation of the WTP.

AENOR finally certifies, certifies and grants the EPD, in accordance with International Standard ISO 14025, which defines the requirements that these Environmental Declarations must meet, including third party verification, and European Standard EN 15804 (as a product intended for construction) which facilitates the recognition of the environmental information of construction products in Europe, as it constitutes a harmonised and recognised reference. Providing a reliable, relevant, transparent, comparable and verifiable environmental profile to highlight an environmentally friendly product, based on life cycle information (LCA), prepared according to Product Category Rules (PCR); according to international standards and quantified environmental data.

The example of LEED® certification

LEED® CERTIFICATE, an acronym for Leadership in Energy & Environmental Design, is an American certification system for buildings, developed by the US Green Building Council (USGBC), to promote the development of sustainable and energy-efficient buildings.

For Spain, USGBC recognises Green Building Council España (GBCe) as the sole representative at the LEED development table, to provide all the necessary information on this certification of buildings.

The system is characterised by providing an evaluation of the sustainability of the building by assessing, through a points system, its impact in the following SEVEN main areas:

1-. Sustainable location.

2.- Efficiency of water use.

Energy efficiency, renewable energies and atmospheric emissions. 4.

4.- Materials and natural resources.

5.- Indoor environment quality.

6.- Innovation in design.

7.- Regional priority.

The Filita naturpiedra gives points, depending on the application, in the following areas: energy efficiency, materials and natural resources, quality of the indoor environment and regional priority.

Depending on the amount of points scored in each area, the following levels of certification can be issued:

– LEED Certificate (Basic)

– LEED Silver Certificate

– LEED Gold Certificate

– LEED Platinum Certificate