Technical Data > Technical data Bernardos phyllite > Quarries and materials

Some kilometres away from the town of Bernardos in the province of Segovia, one can find two slate quarries belonging to the company Naturpiedra Jbernardos, which exploits, prepares, controls and sells the rock extracted from those historical deposits.

The company possesses numerous installations in the town, well-functioning machinery and a very experienced personnel, in order to be able to meet the exigencies in terms of quality and sustainability which are nowadays required for rock materials in the international market (Picture II-4).

All these circumstances imply the need to count on the highest qualifications from the most demanding markets, established on the basis of laboratory trials as follows:

According to European standards, based on UNE-European Norm standards.

The Bernardos slate complies with the highest standards of quality, based on the applicable regulations defined by the classification codes W1, T1, S1 and A1, which are described as follows:

• W1: very limited water absorption (< 0,6), indicating an excellent resistance to frost and very low sensitivity to degradation

• T1: no oxidation or changes in structural appearance when testing over the thermal cycle

• S1: no structural alternations or changes in colour when exposed to Sulphur dioxide (SO2)

• A1: reaction to being exposed to fire, considered as compliant

According to the ASTM – American norm

Bernardos slate complies with the highest possible quality level as an S1 grade according to the ASTM-C406. This norm is the standard approved test report for roofing slates. It contains 3 different types of tests as follow:

Test ASTM – C121 calculate the Water Absorption. Slate is considered as an S1 if the máximum does not exceed 0.25% – Bernardos slate have passed with 0.091%.

Test ASTM – C120 calculate the Flexure (Breaking Load). Slate is considered as an S1 if the resistence is over 575 lbs – Bernardos slate have passed with 991 lbs.

Test ASTM – C217 calculate the Weather Resistance (Depth of Softening). Slate is considered as an S1 if the máximum does not exceed

0.02 in – Bernardos slate have passed with 0.0002 in.

In relation to the American Norm ASTM C406 criterias, Bernardos slate have passed the highest level of quality which gives a life expenctancy of over 75 years.

For a better understanding of the ASTM C-406 norm, it is important to understand that the classification is S1, S2 or S3, being S1 the highest grade. Slates approved as an S1 will be guaranteed to have a lifespan of 75 years and over, as an S2 it will be between 40 and 75 years and as an S3 it will be between 20 and 40 years.

Thanks to the combination of an exceptional natural product and the experience and professionalism of the team at Naturpiedra Jbernardos, more than 80% of the production is exported, and can then be found in more than 25 countries across all five continents.

THE BERNARDOS QUARRIES

In Bernardos, in addition to the currently active quarries, one can find numerous remains of previous exploitations scattered across the flanks of the Eresma river, which serve as proof of the continuity of the mining activities starting in mid17th century.

Among these, it is worth highlighting − because it shows a notable degree of organisation − the exploitation founded in the early 20th century by the British company The Bernardos Slate Quarries Ltd, constituted in London in 1909 (see Part I), which demonstrates that Bernardos slate already held a level of international recognition at that time.

Naturpiedra Jbernardos currently owns many quarries in the area containing various types of materials, two of which are used for the extraction of phyllite, and are officially registered under the following names:

• Cantera El Castillo

• Cantera Engorduro

The quarry of El Castillo (Cantera el Castillo) contains pieces of ground and amounting to a total area of 10 hectares. A recent geological study confirmed that there are reserves of 500,000 tons of phyllite of prime quality which can be used for roofing.

The quarry of Engorduro (Cantera Engorduro) is one of the oldest exploitations in Segovia, and, taking into account the mining sites, the debris facility and the manufacturing plant, can boast an available area of more than 90 hectares. The confirmed reserves exceed 2,000,000 tons.

NOTE.- These figures could be multiplied by 10 if one includes the potential reserves contained in the slaty massif of Bernardos.

HISTORICAL VALUE AS AN INSTRUMENT FOR RESTORATION

If one had to highlight a relevant property of the Bernardos slate, in addition of its purely technological properties, it is undoubtedly worth noting the slate’s full adaptation to historical edification, as an appropriate material for restoration works.

Indeed, the historical background presented in Part I of this publication mentions numerous and symbolic references to this slate, dating back to the 16th century, when it was chosen by King Phillip II for the construction of the roof in various royal works. This started with the Palace of Valsaín and the activity continued throughout the 17th century until it culminated in its most emblematic construction − the Monastery of San Lorenzo del Escorial.

The quality, resistance and aesthetic value of the materials prompted the Crown to proclaim the Bernardos sites as Royal Quarries, which encouraged the use of this slate in numerous edifications.

In addition, the historical relevance is complemented by the recommendations of great experts from international entities in charge of the conservation of the world’s historical and cultural heritage. In this context, two important documents must be mentioned: the Athens Charter of 1933 and the Venice Charter of 1964, which was later elaborated on the guidelines of the former.

The Athens Charter is the first document to formulate recommendations and general principles for the conservation of historical and artistic monuments. It was drawn up by a group of experts through the International Congress of Intellectual Cooperation and under the auspices of the League of Nations.

The principles for the conservation of monuments established by the Charter − such as the need to respect the historical and artistic works of the past without belittling the style of any epoch, or to ensure that the new materials used are recognisable − are still relevant today, and have served as the basis for subsequent documents which have come to expand the scope of recommendations.

The Venice Charter was drawn up in 1964 within the framework of the International Council on Monuments and Sites (ICOMOS) created following a proposal put forward by UNESCO. The text of the ICOMOS conference contains a series of articles, some of which relate to restoration and read as follows:

ART 1. The concept of a historic monument embraces not only the single architectural work but also the urban or rural setting in which is found the evidence of a particular civilization, a significant development or a historic event. This applies not only to great works of art but also to more modest works of the past which have acquired cultural significance with the passage of time.

ART 2. The conservation and restoration of monuments must have recourse to all the sciences and techniques which can contribute to the study and safeguarding of the architectural heritage.

ART 3. The intention in conserving and restoring monuments is to safeguard them no less as works of art than as historical evidence.

ART 7. A monument is inseparable from the history to which it bears witness and from the setting in which it occurs. The moving of all or part of a monument cannot be allowed except where the safeguarding of that monument demands it or where it is justified by national or international interest of paramount importance.

ART 9. The process of restoration is a highly specialized operation. Its aim is to preserve and reveal the aesthetic and historic value of the monument and is based on respect for original material and authentic documents. […]

ART 16. In all works of preservation, restoration or excavation, there should always be precise documentation in the form of analytical and critical reports […]. This record should be placed in the archives of a public institution and made available to research workers. […]

In this context, the Bernardos slate is a product which can be clearly identified from its origins, has been used for almost 500 years and has been an essential part of many emblematic constructions of the Spanish architectural heritage. It is therefore crucial to protect it in order to continue with restoration works, in accordance with the recommendations which have been voiced in this respect at the international level.

A good illustration of the importance of the Bernardos slate as historical material lies in the wide-ranging and well-documented construction works mentioned in Part I, covering the period from the mid-16th century until the beginning of the 19th century.

TECHNOLOGICAL PROPERTIES OF THE SLATE

The properties of the Bernardos slate are to be understood in the context of their intended use as construction material, in accordance with the regulating framework developed by European committees on standardisation.

Following this criterion, the characterisation tests can be divided into two groups.

It must be noted that the herein mentioned results are those which were considered as most representative among the samples used for the tests. Throughout the years, Naturpiedra Jbernardos has been requesting different laboratories at national and international level to carry out the following tests:

Characterisation tests for the slate used for roofing, following UNE EN 12326- 2, defined in the Sub-committee CEN TC128/SC8

Petrographic analysis

• Macroscopic description

Colour: Medium grey, N5 − following Rock Color Chart, Munsell (2009).

Rock with high schistosity and very fine grain. The sample is compact and tends to separate along sub-parallel planes under pressure. There is no indication of agitation when the rock is subjected to hydrochloric acid diluted into 10%. The abundance of micaceous minerals gives the material a distinctive glassy look and, when the sample is slightly tilted, strips perpendicular to the schistosity become apparent.

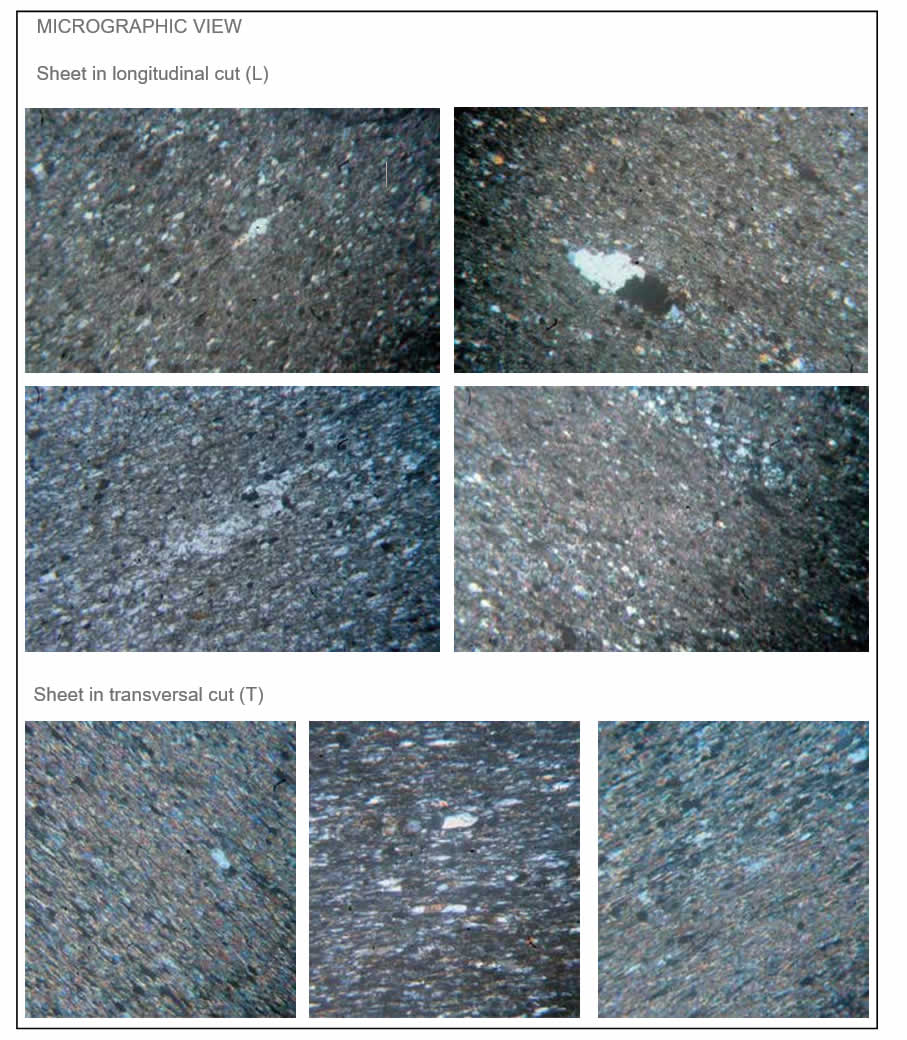

Two slabs of slate were sampled:

– In a plane perpendicular to the exposed side and parallel to the longitudinal direction.

– In a plane perpendicular to the exposed side and perpendicular to the longitudinal direction.

• Microscopic study

Mineral composition:

– Main components: quartz, sericitic-argillaceous minerals (sericite-glauconite), muscovite, opaque.

– Accessory components: biotite, tourmaline.

Texture: Similar to siltstone with sporadic meta-psammite strips the size of very fine-grained sand.

Observations:

Rock with low-grade regional metamorphism, within the facies of green schists. The biotite presence accounts for the metamorphism.

The sample contains an abundance of subrounded quartz (with a level of roundness comprised between 0.3 and 0.5) and the crystals have their main axis oriented in the same direction as the main schistosity S1.

The quartz is irregularly distributed across the slab, frequently with undulatory extinction, a clear indication that deformation processes have occurred.

The size of grains are comprised between the grain-size fraction of silt and very fine-grained sand, the typical range for phyllite.

The most abundant components of the sample are microliths of sericitic-argillaceous minerals, with a subparallel orientation and defining the main schistosity S1. This is most likely to be sericite-glauconite.

The rest of the composition is made up of dispersed opaque granular compounds, probably iron oxides or hydroxides, which can form short veinlets, and, in very small quantities, biotite with low-grade crystallinity and possible traces of tourmaline (difficult to ascertain due to its small size).

The rock is seemingly derived from very fine sediments the size of silt and with a quartz-argillaceous composition, which helps preserve a certain degree of stratification due to small variations in the depositional conditions and which lead to some accumulation of quartz.

Given the grain size and the level of metamorphism, the rock is halfway between slate and schist, and can be described as phyllite. This term is still in commercial use for decorative rocks.

However, according to current petrographic classification criteria for metamorphic rocks (British Geological Survey report 1999 number RR 99-02 Classification of metamorphic rocks, Chapter 9.5 – Slate and Phyllite), it is advised not to use this term since it encompasses meta-sedimentary rocks (as it is the case here) as well as rocks with dynamic metamorphism such as phyllite-mylonite. It is hence usually preferred to use a term referring to the type of sediments from which it is derived, the rock thus being classified as meta-siltstone.

Such classification criterion also suggests that the adjective phyllitic must be added when describing rocks which have the distinctive glassy look and in which the argillaceous microliths can be seen through an optical microscope (criteria used to distinguish phyllites).

Proportion of minerals and average grain size:

Mineral content (in %)Particle diameter (in mm)

Quartz 37 % Between 0.015 and 0.12 mm

Argillaceous minerals 58 % 0.01 mm

Opaques 5 % Between 0.03 and 0.08 mm

Structural type: longitudinal (O) transversal (f)

Level of accumulation of mica: longitudinal: 65, transversal: 69

CLASSIFICATION: Phyllite (Phyllitic meta-siltstone)

Determining the modulus of rupture and the typical modulus of rupture.

Average modulus of rupture

– Longitudinal direction: 55 N/mm2

– Transversal direction: 27 N/mm2

Typical modulus of rupture

– Longitudinal direction: 41 N/mm2

– Transversal direction: 21 N/mm2

Orientation of the maximum modulus of rupture: LONGITUDINAL.

Water absorption.

Average value: 0.2 %

Classification code: A1 (frost resistance).

Frost resistance.

Not necessary since it is a A1-type slate in terms of absorption.

Determining the content of calcium carbonate and non-carbonate carbon through thermal catalytic decomposition.

Calcium carbonate content (Cc): 0.2 % (<5%, does not require an increase in thickness).

Non-carbonate carbon content (Cnc): 0.08 % (<2%, in accordance with the norm).

Exposition to sulphur dioxide (SO2)

Alterations: none, and no changes in colour

Test results code: S1 (resistant to atmospheric SO2, does not require an increase in thickness).

Thermal cycle test.

Alterations: no oxidation, and no significant changes in appearance.

Test results code: T1 (good behaviour upon thermal changes)

Termal change resistance.

Characterisation tests for the slate for other uses such as paving, tiling and masonry, etc, following the procedures developed by the Committee regulations CEN TC 246/WG2 and CEN TC 125.

Petrographic study. See previous petrographic study. Picture II-8

Petrographic classification (based on UNE-EN 12670:2003): PHYLLITE

Water absorption with respect to atmospheric pressure (UNE EN 13755)

Average value: 0.1 %

Bending strength (UNE EN 12372)

Average value: 65 N/mm2

Expected lower value: 60 N/mm2

Resistance to freezing (UNE EN 12371)

Bending strength after 144 cycles of frosting/ defrosting

Average value: 65 N/mm2

Expected lower value: 63 N/mm2 Alterations: none

Apparent density and open porosity (UNE EN 1936)

Average value of apparent density: 2750 kg/m3

Average value of open porosity: 0.3 %

Breaking load for fixings (UNE EN 13364)

Average value of breaking load: 3550 ±600 N

Expected lower value: 2700 N

Resistance to slipping (UNE EN 12633)

Table of results

Table of results

Resistance to age through thermal shocks (UNE EN 14066)

Mass variation: 0.03% − Irrelevant

Average value of variation of the modulus of dynamic elasticity: -0.3% − Irrelevant

Resistance to fixings (UNE EN 13364): 3550 N